The tube roller mixer is designed for testing and experimenting with raw material samples in the new energy battery industry. With over ten years of experience in manufacturing roller mixers, we have established strong partnerships with renowned battery manufacturers such as CATL (Contemporary Amperex Technology Co. Limited).

Our tube roller mixer is equipped with multiple product lines, ensuring high quality, cost-effective, and steady output. It is an essential equipment for battery research and development, providing reliable and accurate mixing results.

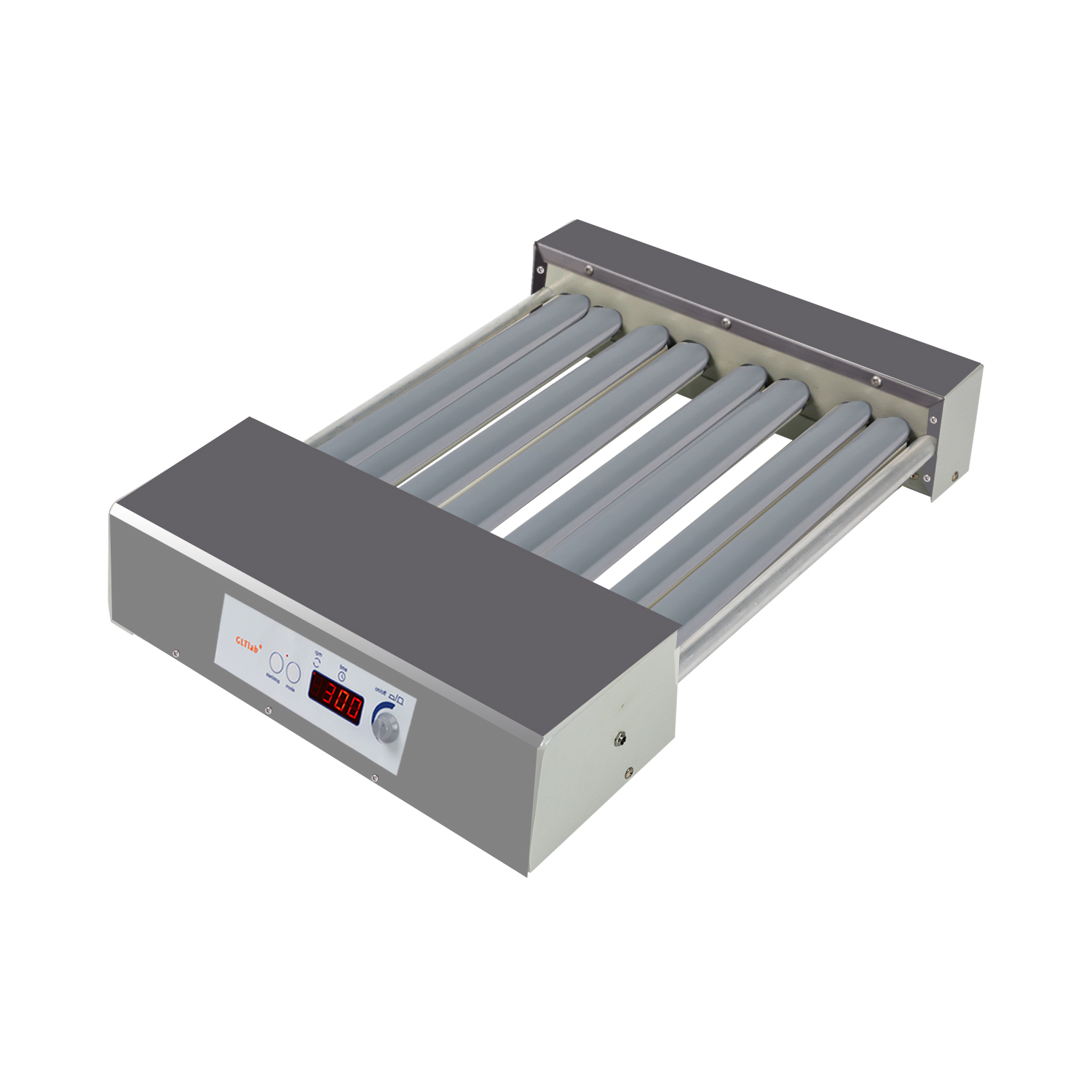

| Action Mode | Rolling |

| Number of Rolling | 8 |

| Speed | 5-300rpm (Max 1000) |

| Maximum Load | 10.0 KG |

| Control Mode | Numerical Control |

| Regular Time | 1s-200H |

| Roller Size | 340*30mm(L×D) |

| Dimensions | 556*392*98mm(W*D*H) |

| Weight | 9.0 KG |

| Power | 12V5A, 19V3A, 60W |

The Tube Roller Mixers mix samples through the simultaneously rolling action of the tubes and the carried vessels (bottles, test tubes etc.). As the tubes rolling, the vessels are rolling too, causing continuous mixing of the liquid inside the vessels. The most advanced features are the convenient sample handling and the accommodation of various types of vessels in the mixer without adding any adapters or accessories compared to other types of mixers.

There are two types of action on the tube rolling mixers:

1.With a slightly tilted angle on the axes of the tubes, a gently rocking action happens when tube rolling. It helps

the mixing efficiency of some viscous samples in gentle mode. And it is ideal for mixing blood samples, viscous substances and liquid-solid suspensions where minimum aeration is required or for aiding de-frosting of samples.

2. A rolling action without rocking effect. Samples are mixed with the continuous rolling action.

There are several unique features compare to those rollers in market:

1.) Capable removing tubes from the machines to increase the distance between the rollers to accommodate

larger containers in 1D models.

2.) The maximum rolling speed is 1000rpm, The standard roller mixer speed is 5-300.

3.) Rolling in two directions: Clockwise and anti-clockwise.

4.) Timer to set up the alternate rolling direction.

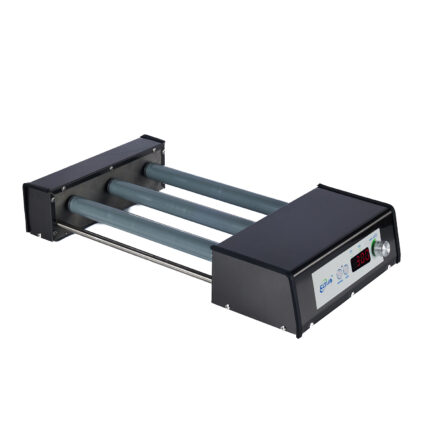

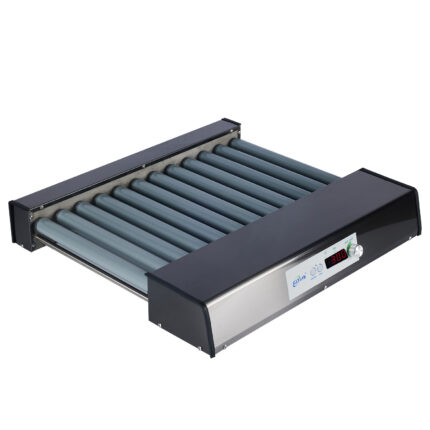

The LTR series are having nine rollers which suitable for large vessels and tubes. And the MTR series are smaller version with six rollers. The loading capacity si 10 KG for the above mixers.