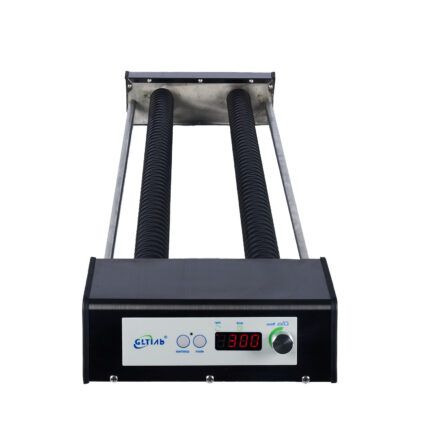

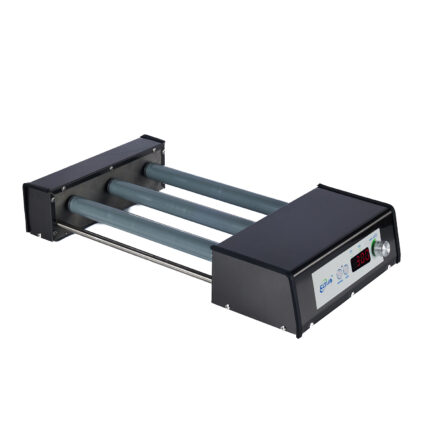

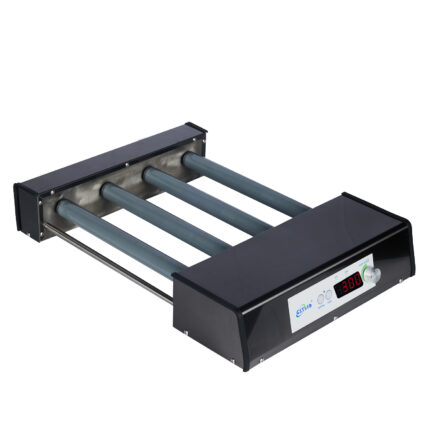

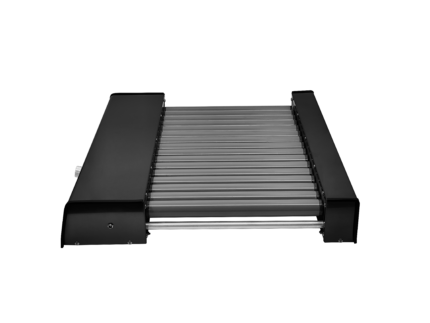

Operations Manual

Models: TR-1L, TR-2L, LTR-1D, LTR-2D, LTR-3D, TR-8A, TR-8B, MTR-1D, MTR-2D, MTR-3D, TR-6A, TR-6B, TR-10A, TR-10B, TR-20A and TR-20B

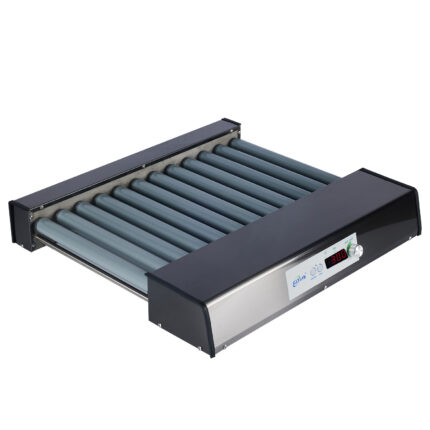

Tube Rollers

Introduction:

Tube Rollers are quietly with high loading machines to let the round sample containers on the top of the rollers to either rolling and rocking (for some models) or only rolling with adjustable speed and direction for the purpose of mixing. The machines are very useful for continuous mixing of viscous and non-viscous liquid for preventing clotting; solidify of special glue or other chemical reagents; mixing the solid/solid, solid/liquid components homogeneously and widely used in biological, chemical and industrial applications.

With our proprietary techniques and designs, we developed many different types of tube rollers for many applications.

I. Specifications:

Speed: 5 rpm to 300 rpm, the speed is based on the speed of the rollers (32 mm Diameter). When the container diameter greater or smaller than the roller, the real speed of the containers are reversed proportionally to the speed of the rollers. For example, when set at 300 rpm, the speed of container with 90 mm diameter is 300 rpm / (90/32), about 106 rpm.

Timer: 1 sec. to 9 hours or Continuous

Loading: 10 kg, > 10 Kg for some models

Dimensions: various for different models

Weight: various for different models

Electrical: 100 to 240VAC, 50-60Hz, ranging from 5A to 20 A for various loading of machines.

Operating environment: 4°C (cold room) to 60°C

Warranty: 2 years

II. Product Set-Up:

Place the roller on a clean and stable surface. Plug the roller into a properly grounded outlet. Turn on the roller by pressing once on the main knob.

III. Product Operation:

Set the Speed: Press the “Mode” key until the small red LED under “RPM Mode” is illuminated. Then adjust the speed from 5 to 300 rpm with the control knob.

Set the Time : Press the “Mode” key until the small red LED under “Time Mode” is illuminated. Then adjust the time from 1 second up to 9 hours. NOTE: The time can also be set to run continuous by setting the time to “– –“.

Set the Rotating Direction: Press the “Mode” key until the small red LED under “RPM Mode” and “Time Mode” are not illuminated. Then adjust the direction to “C” for Clockwise or “A” for Anti-Clockwise. For Alternate Direction Mode (designed for more intense mixing) set the direction to a numeric value of 120°, 180°, 240°,.300°, 360°, 720°, 1080°, 1440°. The roller will then roll the desired setting. stop and roll in the reverse direction, then repeat.

Press the “Start/Stop” key to begin the rotation. At the end of the desired time, the rotator will stop automatically, and an end of cycle alarm will beep. NOTE: A cycle can be stopped at any time by pressing the “Star/Stop” key while rolling. The motor comes with auto-protection mode. When overloaded, the roller will stop, press “Start/Stop” key, then pull out the DC plug to turn off the machine, after a few second, re-plug the DC plug, it will automatically save the pre-set parameters, and just press the “Start/Stop” key to run again.

IV. Care and Maintenance:

No routine maintenance is required other than to keep the unit clean. Cleaning can be done with a damp cloth. Avoid the use of solvents as they may damage the product housing.

Service and Contact:

In the event that service or technical support is required, please contact contact@gltqclab.com